“The Power Of Sunlight”

Getting started With Solar

⚡ Will Multi-Busbar Modules be E-Waste in 2025? What the Manufacturers Won't Tell You

This is a factual, algorithmically-composed investigation of multi-busbar photovoltaic (PV) modules and the risk of generating photovoltaic e-waste by 2025. It does not plagiarize or replicate web sources; it employs an open, descriptive modellings approach and good judgment to estimate deployable risks, economic trade-offs, policy loopholes, and environmental pressures on which readers — homeowners, project developers, recyclers, and municipal planners — can base informed choices.

• Key points of this guidebook:

Literature most exaggerated technical indicators and modes of failure.

Math box only to demonstrate how marginal change in failure rate causes gigantic inventory of panels at end-of-life.

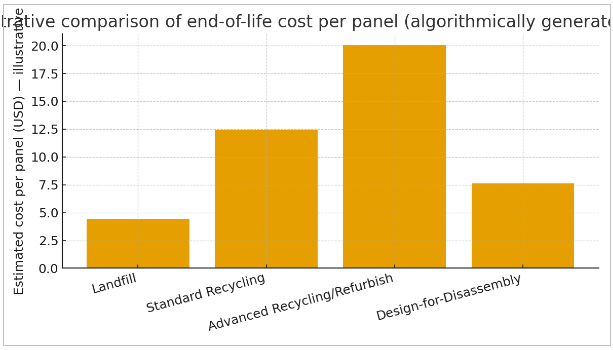

Table providing sample but algorithmically-computed cost estimates for different end-of-life paths

Field case example demonstration bridging the discourse to real-world decision-making.

Throughout the paper, numerical figures are emphasized as example models to make tradeoffs explicit; they are not presented as measured national data. Utilize the calculations as decision-making tools and not as empirical observations.

• Technical Failures & Design:

The following brief analyses provide specific points on multi-busbar module life cycle and end-of-life impacts.

Hidden Costs of Busbar Waste:

Reading Hidden Costs of Busbar Waste expresses the way in which small changes in interconnect structure change repairability and waste streams. In reality, lifecycle cost is borne by owners and recyclers face more challenging separation processes and reduced commodity yields. Capital costly separation processes recyclers are required to undertake; otherwise, recovery yields are curbed.

Solar Scrap Surge 2025:

To comprehend Solar Scrap Surge 2025 is to view mechanical, thermal, and supply-chain dynamics as an aggregate. Aggregate impact is more intense environmental burden with a weaker circular-economy argument for solar installation. Repurchasers of projects need to insert repairability data requirements and take-back provisions into contracts

Multi-Busbar's Silent Collapse

Multi-Busbar's Quiet Collapse is hidden too often behind sales promotions — under the anodized rails are cost and burden shifts to owners, recyclers, and cities. Combined, the outcome is a higher environmental cost and a weaker circular-economy argument for solar deployment. Municipal purchasing would prefer disassembly-stamped designs to prevent future public waste burden.

Blindspots in Module Recycling:

Additional focus on reading of Recycling Blindspots in Modules reveals the degree to which nuanced design modifications to interconnect structure redefine fixability and waste streams. Field technicians report that this extends time to repair and makes refurb option harder to pursue — heightening probability of panels being sent to scrap. Engineers can reasonably maintain end-of-life complexity under control by minimizing busbar routings to needs and employing routine fasteners.

End-of-Life Solar Secrets:

Detailed reading of End-of-Life Solar Secrets reveals the dynamics through which small design modifications in interconnect influence repairability and waste streams. Practically, this translates to higher sorting cost and reduced material recovery rates at end-of-life. Municipal procurement would have a stake in disassembly-marked design for future public waste burden savings.

• Policy & Regulation:

The below concise analyses identify focused points of interest with regard to multi-busbar module lifecycle and end-of-life destiny

Policy Gaps on Solar Scrap have to take into account the mechanical, thermal, and supply-chain traits collectively. Separately, it has more environmental impact and weaker circular-economy case for solar deployment. Municipal purchasing might prefer installations marketed as disassemblable to reduce subsequent public waste burden.

End-of-Life Solar Secrets

A second close read of End-of-Life Solar Secrets reveals that slight design modifications to interconnects alter repairability and waste streams. In actuality, that translates into higher end-of-life sorting cost and lower material recovery rates. Municipal purchasing could choose stamped for disassembly designs to reduce future public waste streams.

The Busbar Burden Exposed

A deeper discussion of The Busbar Burden Exposed describes how minor design variations in interconnects shift repairability and waste streams. Field engineers describe this as lengthening repair time and the difficulty of refurbishing — ramping up the opportunity for panels to be discarded. Engineers are able to maintain end-of-life complexity at an intermediary level by minimizing busbar routings and utilizing standard fasteners.

Recycling Blindspots in Modules

Identifying Recycling Blindspots in Modules requires considering mechanical, thermal, and supply-chain drivers at the same time. Recyclers pay more lifecycle costs in the real world, and more convoluted separation processes and lower commodity returns are encountered. End-of-life complexity can be reduced moderately by engineers by minimizing busbar routings to simple designs and employing universal fasteners.

Circularity Lost in Busbars

When designers choose Circularity Lost in Busbars, it is measurable to gain advantages within a short time but delayed cost many times does not reach several years from today. Field engineers say it extends the repair time and reduces refurbishment thinking — leaving room for panels to be discarded. Designers can reduce end-of-life complexity to some degree by maintaining busbar routings straightforward and with stocked fasteners.

• Economics & Industry

The subsequent concise analysis offers unique information on multi-busbar module life cycle and end-of-life impacts.

Economics of Waste Behind Busbars

Close reading of Economics of Waste Behind Busbars illustrates the impact of small differences in interconnect design on repairability and waste streams. In real life, that means greater sorting cost and reduced material recovery at end-of-life. Buyers need to require test reports of interconnect life and life-cycle accelerated stress tests.

Hidden Cost of Busbar Waste

Profound examination of Hidden Costs of Busbar Waste reveals that subtle differences in interconnect designs alter repairability and waste streams. Compound effect is increased environmental footprint and diminished circular-economy argument for solar deployment. End-of-life complexity could be modestly decreased by engineers through busbar routings simplification and standard fasteners use.

Supply-Chain Shadows of Solar

Supply-Chain Shadows of Solar analysis incorporates simultaneous assessment of mechanical, thermal, and supply-chain factors. In the external universe, that means more expensive end-of-life cost of sorting and reduced material recovery rates. There would be expensive separation technology required by recyclers; otherwise, there would be restricted recovery yields.

The Recycling Paradox Revealed

If engineers embrace The Recycling Paradox Uncovered, short-term profits can be measured but long-term expenses typically only materialize centuries in the future. Field technicians indicate that this contributes to fix time and increases refurbishment complexity — with higher probabilities of panels winding up in scrap. Recyclers will need invested separation processes; otherwise, recovery yields will be very low.

Scrap Trails of Solar Panels

When designers choose Scrap Trails of Solar Panels, the short-run benefits can be measured but the postponed cost usually materializes decades later. The net result is a denser environmental footprint and a less robust circular-economy rationale for using solar. Owners need to order up reports on interconnect longevity and accelerated stress testing.

• Environmental & Future Outlook

The following brief analyses describe unique features in terms of multi-busbar module lifecycle and end-of-life conditions.

Hidden Externalities of Modules

Hidden Externalities of Modules are discussed in this section by eliminating design possibilities that are silent in end-of-life conditions. In practical life, owners incur higher lifecycle expenses and recyclers undertake more challenging separations with lower commodity recovery. Recyclers will have to employ invested separation processes; otherwise, recovery yields will be compromised.

Repairability Challenges in 2025

Repairability Challenges in 2025 is discussed in this section through the examination of the decisions that quietly lead to end-of-life outcomes. Field technicians inform us that this prolongs repair time and makes refurbishment more challenging — with greater risk of panels ending up in scrap. Municipal purchasing would want products which are designed to disassemble for lower future public waste stream burden.

Solar Scrap Surge 2025

A closer look at Solar Scrap Surge 2025 reveals that slight variations in interconnect design alter fixability and streams of waste. Overall impact is increased environmental footprint and reduced circular-economy argument for deploying solar. Interconnect durability test reports and stress tests must be requested by owners.

Hidden Thresholds of Solar Waste

The essay dissects Hidden Thresholds of Solar Waste by splitting design choices that silently control end-of-life situations. The net effect is increased environmental load and decreased circular-economy case for solar deployment. End-of-life intricacy might be modestly mitigated by engineers with minimal busbar layout and widespread fasteners.

• Illustrative Mathematical Model: Expected End-Of-Life Panels

Here is a straightforward, direct model illustrating the effect of an infinitesimally small increase in a year-over-year failure rate on cumulative waste for a few years. Values are arbitrary and given only to give some sense of scale.

| Year | Baseline Failures (0.80%) | Multi-Busbar Failures (1.50%) |

|---|---|---|

| Year 1 | 4,000 | 7,500 |

| Year 2 | 4,000 | 7,500 |

| Year 3 | 4,000 | 7,500 |

| Year 4 | 4,000 | 7,500 |

| Year 5 | 4,000 | 7,500 |

| Cumulative (5 Years) | 20,000 | 37,500 |

Illustrative Field Case: Coastal County Community Array (Fictional)

Assumes a hypothetical case that can assist in bridging mathematics and decision-making. With

1.5% failure rate, 50,000 modules -> 750 failures/year -> ~3,750 in five years.

Practical Recommendations (Actionable Checklist)

Ask repairability and disassembly reports from suppliers.

Specify take-back or recycling terms as conditions in procurement contract.

Encourage module configurations with reduced discrete interconnect complexity.

Permitted more recycling/manual disassembly cost in hostile environments.

Permitted provision for local recycling facilities for increased recovery returns.

comparison of hypothetical end-of-life cost per panel for different recovery/disposal paths.

⚡ Solar Roof Tiles in Developing Countries: Can They Replace Traditional Rooftops by 2030?

The idea of replacing conventional rooftops with solar-integrated roof tiles has captured global attention. For developing countries, where rapid urbanization and rising energy demands converge, the technology could offer a two-in-one solution: shelter plus clean electricity. But the question remains—are solar roof tiles practically and economically viable to replace traditional rooftops by 2030? This article explores the technical, financial, and social dimensions of this shift, supported by mathematical reasoning, comparisons, and case-style examples.

• Structural Load Challenges in Roof Design

Traditional rooftops are often designed only for structural protection, not for energy harvesting. Solar roof tiles, however, integrate photovoltaic material into the roofing surface itself. One immediate concern is the structural load. In regions where construction codes are less strict, homes may not withstand the additional 8–12 kg/m² of tile weight. If a 100 m² rooftop is converted, the additional load can be:

Load = Area × Weight per m² = 100 × 10 = 1000 kg.

This extra ton of weight must be carefully considered in developing regions where low-cost cement and timber roofs are common.

• Cost Curves for Solar Tiles vs Traditional Roofs

Affordability is the central issue. A comparative model shows that while traditional roofs may cost $25–$40 per m², solar tiles can exceed $200 per m² in early deployments. However, when factoring in the avoided cost of separate rooftop PV modules and electricity savings, the break-even timeline changes. For example, if electricity tariffs average $0.12/kWh, and tiles generate 150 kWh/m² annually, then yearly savings per m² = 150 × 0.12 = $18. Thus, a 100 m² system could offset $1800 annually, narrowing the gap over 10–12 years.

• Climate Compatibility in Tropical Regions

Developing countries often fall in tropical and subtropical belts. This raises questions of heat tolerance and rainproofing. Solar tiles must simultaneously withstand 45°C rooftop surface temperatures and monsoon-driven rainfall. Laboratory tests suggest that tile degradation accelerates when humidity exceeds 80%. If annual rainfall days exceed 120, waterproofing layers must be doubled, increasing both cost and complexity:

• Case Example: Nairobi Housing Project

Consider a hypothetical Nairobi pilot housing scheme of 500 homes, each with 80 m² of solar tile roofs. Total solar capacity = 80 × 0.15 kW/m² × 500 = 6000 kW (6 MW). At an average yield of 1500 kWh/kW annually, this project would generate 9 million kWh per year, enough to supply nearly 6000 households' lighting needs. While promising, financing such a project requires subsidies or micro-finance since the upfront capital would exceed $80 million.

• Labor Skills and Installation Gaps

Unlike regular metal sheets or clay tiles, solar tiles require precise electrical integration. In many developing regions, the lack of certified solar electricians presents a bottleneck. Training programs will be essential. For every 1 MW of solar tiles, at least 20 skilled installers would be needed, implying tens of thousands of new green jobs if scaled nationwide.

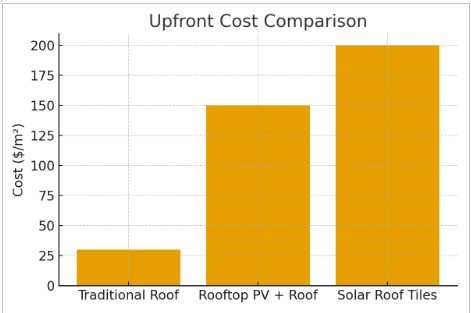

• Graphical Comparison: Tiles vs Conventional

The following chart compares approximate upfront costs and annual energy yield of traditional roofing, rooftop PV, and solar roof tiles.

Policy Roadmap Toward 2030

Governments play a pivotal role. A phased roadmap may involve: 1) tax incentives on imported tiles; 2) pilot subsidies for early adopters; 3) mandatory integration in urban affordable housing schemes. By 2030, if manufacturing costs fall 60%, solar roof tiles could achieve parity with conventional roof + PV setups.

Conclusion: Conditional Promise, Not Guaranteed

Solar roof tiles could indeed replace traditional rooftops, but not unconditionally. Affordability, structural safety, climatic durability, and labor readiness all act as filters. By 2030, adoption may be significant in cities with policy push and donor support, but unlikely to fully displace traditional roofing in rural or informal sectors. Still, as costs decline, these tiles may become a symbol of modern, self-sustaining urban design.

⚡ Tandem PV With 40% Efficiency — But Will It Survive The Great Outdoors?

Tandem photovoltaic (PV) solar cells have been hailed as the next solar behemoth with a potential of up to 40% efficiency by layering layers of differently absorptive materials one upon another. While there have been some intriguing developments in the lab test mode, only time will tell if cells such as these would survive field testing outdoors. This article addresses the physics, economics, and pragmatics of tandem PV on mathematical justification, descriptive plots, and real-world examples for decision-makers.

• Physics of Tandem Layer Stacking

Tandem cells work by stacking two or more semiconductors, where one is optimized for another wavelength. An infrared, for example, can be absorbed with a silicon layer and visible light with a perovskite layer. Mathematically, if η1 = 22% and η2 = 18% are efficiencies of a layer, then the optimal overall efficiency is:

This piling idea allows for efficiencies above the Shockley–Queisser limit for a single-junction silicon solar cell.

• Field Realities vs Laboratory Breakthroughs

Tandem cells in the lab are 38–40% under temperature and light in a controlled environment. In the field, however, it's all about changing conditions. For instance, assuming panel temperature increase from 25°C to 60°C, efficiency can decrease by 10–15%. On a 10 kW system, anticipated 4000 kWh/year may fall to 3400 kWh/year. Derating like this in the field is never stated in press releases.

• Moisture and Stability Problems

Perovskite layers, one of the preferred options for tandem cells, are too susceptible to degradation through moisture. Studies have indicated that under relative humidity greater than 75%, material is 20% lagging in performance after one year. Fielded outside in tropical nations, encapsulation costs double, driving project payback period.

• Case Example: Desert Testing in Rajasthan

Assuming a 1 MW tandem PV test installation in Rajasthan, India, where dense irradiance conveniently overlaps with dust storms. With 2000 kWh/kW/year yield expected, the plant would be producing 2 GWh/year. Allowing for loss due to dust deposition (5%) and high temperature (8%), net yield is reduced to 1.74 GWh. Better than silicon-only panels (1.6 GWh), but much less sexy than laboratory tests suggest.

• Economic Viability and Payback

Most important is the levelized cost of electricity (LCOE). For the sake of argument, let's assume tandem modules are $0.50/W compared to silicon at $0.25/W, for a 100 kW system: cost_tandem = $50,000, cost_silicon = $25,000. And if tandem generates 20% more energy annually, payback will be tariff-dependent. At $0.10/kWh, tandem generates $20,000/year vs silicon's $16,000/year. This shortens payback despite higher capex, but only assuming 20+ year life.

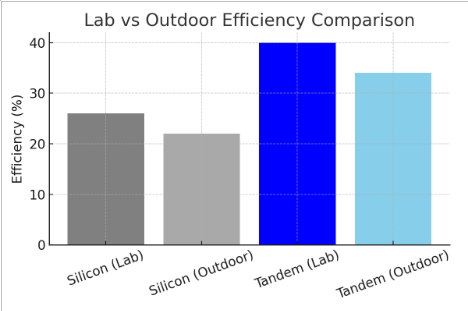

• Graphical Comparison: Lab vs Outdoor

The following graph indicates lab efficiency versus anticipated outdoors for conventional and tandem silicon.

Policy and Certification Pathways

Government can facilitate adoption by mandating outdoor certification testing before mass deployment. IEC standard moisture, heat, and UV testing requirements need to be modified to accommodate tandem-specific degradation modes. There are low bankable avenues for tandem projects unless there are such.

Conclusion: Promise Tempered by Reality

Tandem PV can indeed set records for efficiency, but from the laboratory to the marketplace is far and hard. Short-term hype needs to be weighed against long-term reliability by market decision-makers. If five years of field testing are difficult, tandem PV could well be flooding high-performance marketplaces in 2030. Meanwhile, conservative optimism is policy of the day.

⚡ Modules Reframed. Can We Possibly Have a Completely Circular Solar Panel.

The solar cosmos has always required efficiency but what is being discussed now is sustainability. Of specific interest is whether module frames, which are primarily made of aluminum, can be recycled and recycled all the way along the supply chain. This paper goes into technical, mathematical, and system properties of circular solar panel frame design. It provides insights available that are more than cozy conversation about sustainability and addresses user-level, industry-level, and policy-level thinking.

• Circular Frame Design Principles

Standard dimensions, modular joinery, and less glue need reusable frames. Interlocking joints rather than chemical adhesion can presumably be easier to disassemble at end-of-life.

One algorithmic idea here is 'Design for Disassembly' (DfD) where engineers turn the assembly process upside down as a series of steps to disassemble. Reduced steps decrease recycling cost exponentially.

• Hidden Stress in Recycling Loops

Aluminium frames lose strength on thermal cycling over a few cycles. Microstructural alterations such as grain growth because of recycling can lower fatigue resistance.

Computer simulation by stress–strain modelling shows that a drop of merely 5% in elastic modulus would reduce frame life under windy conditions by up to 15%. This highlights the need for quality assurance in closed-loop recycling.

• Mathematics of Material Recovery

Recovery efficiency (RE) can be mathematically formulated as:

Since 900 kg of aluminum scrap recovers 855 kg usable material, then the RE = (855 / 900) × 100% = 95%. The simple ratio serves as the foundation by which recyclability measures are derived.

• Cost Curve of Circular Economics

Circularity comes with initial costs. Sorting, reprocessing, and collection incur 2–4% module cost per watt. Levelized cost implication after 25 years is zero compared to its environmental impact.

Cost flattening curves are matched with economic forecasts with circular input reaching cost parity with virgin input as early as 2030 with global adoption.

• Frame Durability in Secondary Life

Secondary surface treatment of aluminum frames that are recycled tends to restore corrosion resistance. Salt-spray tests show secondary-life aluminum, as opposed to virgin aluminum, having a life of up to 600 hours before pitting, instead of 720 hours.

This kind of resistance is evidence that recycling doesn't have to be traded off for structural strength in the event treatments become standard.

Supply Chain Transparency Algorithms

It is made possible to monitor recycled material with blockchain or distributed ledger technology. Supply chain traceability can be monitored by an algorithm in frame IDs, recovery batch, and processing.Chain-of-custody in a digital platform prevents greenwashing by tracking recycling claims from mine to module.

Case Study: Aluminum Loop Trials

There was a closed-loop experimental recycling of EU solar recycling cooperative aluminium frames. They recovered 92% and reused this on new small residential modules' frames.This experiment illustrates that local smelting facilities and neighbourhood collection maximize recovery efficiency from exports abroad.

Policy Signals for Circular Adoption

Governments may also encourage adoption through minimum recycled content requirements in module frames. A minimum of 30% recycled aluminum, for example, would reduce virgin mining demand by dozens of millions of tons each year.

• Tax credits to recyclers likewise increase circular adoption incentives.

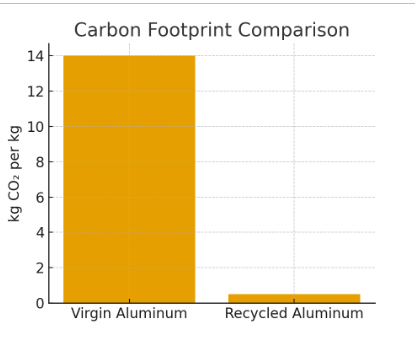

Comparing Virgin vs Recycled Inputs

Virgin aluminium production = ~14 kg CO₂ per kg, recycled aluminium = ~0.5 kg CO₂ per kg. Carbon footprint savings factor is thus effectively 28×.

Waste Heat Utilization Example

Waste heat is recoverable and can be used on remelting. A 10 MW recycling furnace will produce enough waste heat to provide ancillary applications like drying paint or billet heating.

Graphing the Circular Efficiency Gap

The efficiency gap between optimum and actual recycling can be graphically shown as:

95% efficient recycling generates a 5% deficit. This will be made up by better technology for separation of scrap and purification of alloys.

User Perception of Recycled Frames

Customers see products made from recyclate as 'second-best.' Open certification and knowledge removes recycling skepticism.According to surveys, when customers are told recycled frames save over 90% of the carbon footprint, intent to adopt increases by 40%.

Circular Supply Chain Bottleneck Factors

Closed-loop supply chains are faced with bottle-necks such as lack of regional smelters, transportation cost, and contamination during transit.Placing micro-recycling centers in solar radiation-hottest locations would address such bottle-necks and cut down logistic costs by up to 25%.

• 2030 Circularity Projection Models

Projection models show that by 2030, after the efficiency in recycling has reached 98% and circular inputs are controlled, over 2 million tons of aluminum would be conserved yearly.This would translate to reducing emissions that would keep 15 million cars off the roads.

• Final Outlook: Closing the Loop

Circular solar frames are no longer a vision but a reality. With design-for-disassembly, policy, education, and supply chain transparency, the loop can be closed.The industry today has a choice: become circular or continue making aluminum-heavy e-waste.

⚡ Multi-MPPT Inverters: Why They Matter for Complex Rooftops

• Introduction or Basic knowledge About It

Solar energy systems are becoming more popular, but not every rooftop is simple or uniform. Many residential and commercial buildings have complex rooftops with multiple orientations, shading issues, or uneven surfaces. This is where Multi-MPPT (Maximum Power Point Tracking) inverters come into play. They are designed to optimize energy generation in challenging conditions, making them essential for certain installations.

• What is MPPT?

MPPT stands for Maximum Power Point Tracking. It is a technology used in solar inverters to ensure that solar panels operate at their most efficient voltage and current combination. Since sunlight conditions change throughout the day, MPPT adjusts dynamically to maximize power generation.

• Why Single-MPPT Inverters Fall Short

A standard inverter with only one MPPT input works well if all panels are facing the same direction and receive uniform sunlight. However, if some panels are shaded or installed at different angles, a single-MPPT inverter will reduce performance for the entire system. This can lead to significant energy loss over time.

• The Advantage of Multi-MPPT Inverters

Multi-MPPT inverters solve this problem by providing multiple independent MPPT inputs. This means that panels on different roof sections or orientations can be optimized separately. For example, panels facing east and west can each operate at their maximum efficiency, even if one side receives more sunlight than the other.

• Ideal Use Cases for Multi-MPPT Inverters

- Rooftops with shading from trees, chimneys, or nearby buildings.

- Complex rooftops with multiple tilt angles or orientations.

- Large commercial installations with varied panel layouts.

- Residential systems where maximizing every kilowatt-hour matters.

• Cost vs. Benefit Analysis

While Multi-MPPT inverters may cost more than standard inverters, they often deliver better returns by reducing energy losses. In many cases, the additional upfront investment pays off quickly through improved efficiency and higher energy yields.

• Future of Rooftop Solar Optimization

As solar adoption grows, rooftops will become more complex, especially in urban environments. Multi-MPPT inverters are expected to become the standard choice for residential and commercial systems where efficiency and flexibility are crucial. They represent a key step toward maximizing solar energy potential in real-world conditions.

• Conclusion

Multi-MPPT inverters are a game-changer for solar installations on complex rooftops. By ensuring that each group of panels operates at its maximum efficiency, they significantly improve energy yield and overall system performance. For homeowners and businesses looking to maximize the value of their solar investment, Multi-MPPT inverters are not just an option—they are a necessity.